What does ESD mean?

ESD stands for electrostatic discharge and describes the process that occurs when two differently charged objects come together. This discharge is caused by friction or separation of materials. Each of us has experienced this phenomenon, e.g. the electric shock when touching a door handle. Although humans can only perceive an electrostatic discharge in the form of an electric shock from approx. 3,500 volts, damage to semiconductor components already occurs far below this level. This occurs at voltages from approx. 35 volts. About 90 % of electrostatic discharges are far below 3,500 volts and therefore remain undetected by humans. However, they do cause damage to semiconductor components and electronic components.

Appropriate electrostatic discharge protection is therefore an important precaution.

ESD protection has two main functions:

- Prevention of uncontrolled discharge of charge potentials to sensitive components.

- An unnoticed pre-damage of semiconductor components, which can later unexpectedly fail during operation and thus lead to a potential safety risk! (e.g. ABS control units in vehicles).

Why do you need ESD protection in your production?

ESD protection provided by ESD wheels and casters is playing an increasingly important role in areas where sensitive semiconductor technology is installed or transported. An important example of one of these areas is the automotive production. Especially in the production of electric vehicles with highly complex technology, coupled with sensitive electronics and semiconductor components, a lack of ESD protection by ESD wheels and casters can have fatal consequences for the production processes and the transported goods. Improper ESD protection can result in high consequential costs for the entire production process. In the worst case, it can also lead to massive failures of electronic components such as control units, resulting in recalls!

Uncontrolled electrostatic discharges can cause total damage to electronic components (semiconductors) as well as hidden defects, resulting in high costs. These costs can lead to late failures, complaints, repair costs and, most importantly, the loss of your customers and your reputation.

ESD Protection with ESD wheels and casters

Our ESD wheels and casters can help you avoid these unnecessary costs. Casters and wheels can also become electrostatically charged. If the charge cannot be dissipated, the voltage remains in the caster and can only be dissipated when it comes into contact with the ground. Our ESD experts will be happy to advise you on this topic.

For more information or a personal consultation on ESD wheels and casters, please feel free to contact one of our experts. Simply fill out the contact form below and we will get in touch with you.

Our solutions for you

We understand the importance of ESD protection, so we are working to develop a variety of ESD wheels and casters to help you avoid the cost of electrostatic damage and protect your valuable equipment on the production floor. Our ESD wheels and casters are designed to prevent electrostatic charges from occurring in the first place and to safely dissipate unavoidable charges. Voltage spikes are discharged in a controlled manner and cannot discharge abruptly.

Our expertise offers you the following advantages:

- Our know-how about the special challenges in the field of ESD wheels and casters.

- ESD protection, so that your sensitive transport goods remain reliably protected.

- Certified ESD wheels and casters.

The ESD Academy, Germany's leading ESD specialist institute based in Großmaischeid, has certified our mobility solutions according to the ESD standard and confirmed that our products are suitable for use in ESD protection areas (EPA).

Contact us today to prevent any further avoidable costs due to a lack of electrical discharge capability with ESD wheels and casters. To do so, fill out the contact form in just a few steps and one of our ESD experts will be happy to get in touch with you.

ESD protection with conductive components and ESD wheels and casters

Many industries work with sensitive technology requiring electrical conductivity. The automotive and electrical industries are two such sectors that benefit from ESD wheels and casters. But ESD wheels and casters are also essential in factories with explosion hazards. These include pyrotechnic factories, petroleum operations and chemical plants. Here, electrostatic charges can not only have serious consequences for the equipment, but also pose a great danger to people.

Protection for sensitive electronics

Protecting sensitive electronics from electrostatic discharge consists of preventing and controlling discharge. If transport casters are made of materials such as plastic, they can become electrostatically charged within a very short time. We all know this effect when we feel small electric shocks. This effect is often just a nuisance for us, but in certain cases it can pose a high risk. Especially for sensitive electronics, this can have serious consequences, because uncontrolled discharges can severely damage devices. Therefore, the protection of sensitive electronics by ESD wheels and casters is of enormous importance. Thus, ESD wheels and casters are important for every industry. At TENTE we offer ESD wheels and casters for pallet trucks, ESD wheels and casters for chairs and if it should be a little more special, we offer individual ESD wheels and casters for office chairs freely according to your wishes.

Which fields of activity require this protection?

Necessary ESD protection can be found in almost all working areas. You will find it in the automotive industry, in the electrical industry, in warehouses, in production areas, in medicine, in the pharmaceutical industry and in laboratories. Here, people and equipment are affected, so it is important to discharge the electrical discharges on ESD-critical parts and components into the ground. This is achieved through various protective measures, so that electrostatic charges can be prevented.

Guidelines for electrical conductivity

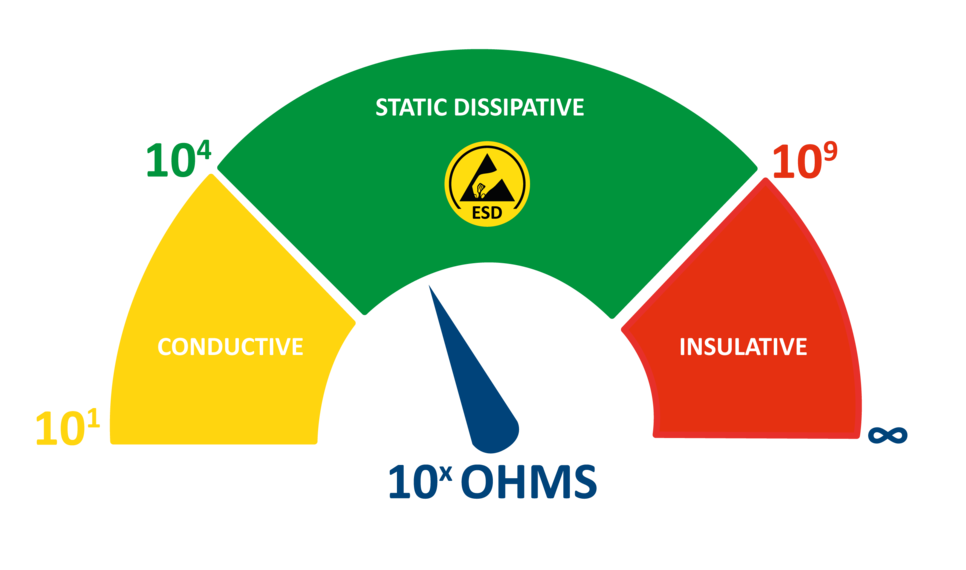

We adhere to the DIN EN 61340 standard, which confirms the certification of ESD wheels and casters. For transport devices, a maximum permissible total discharge resistance of one gigaohm (1x109 Ω) is allowed. Ideally, the discharge resistance should not be less than 10 kiloohms. This is to ensure that the electrical discharge faces electrical resistance as it travels into the ground. Also, the charge will not be discharged abruptly and in an uncontrolled manner, as this can also severely damage sensitive components.

If you have any further questions about ESD wheels and casters, please feel free to contact us.