Stainless casters for longer service life

One solution to these challenges is stainless casters that can carry heavy loads. These casters are specifically designed for demanding environments and can withstand tough conditions. This way, you can be sure that the material will remain durable for a long period of time, even under difficult conditions.

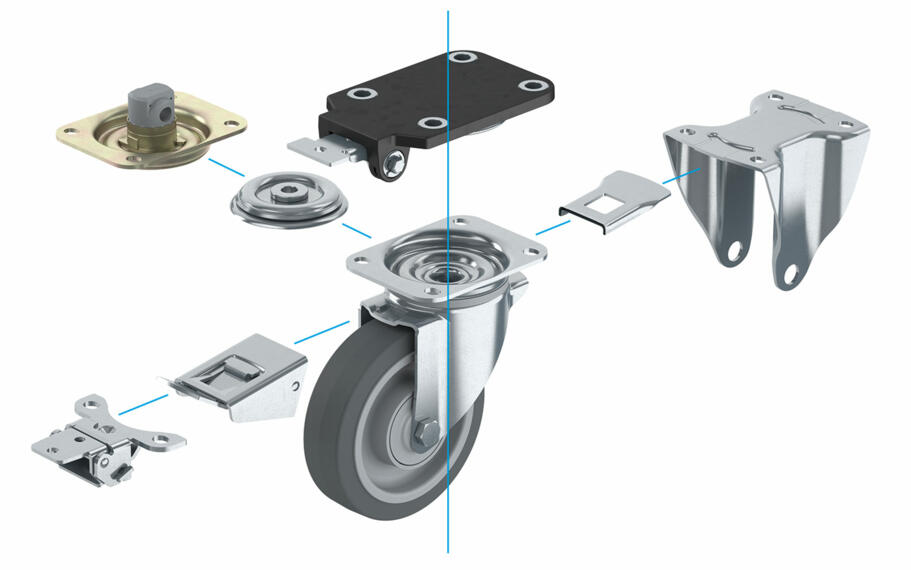

Our solution for you: the all-rounder Alpha

A caster that defies all requirements is our TENTE caster product family Alpha. This caster offers high load-bearing capacities and is a true multi-purpose product. The caster is part of a large product portfolio for different requirements and is suitable for attachment to all types of equipment. Alpha is also available in stainless steel, making it suitable for special environmental conditions such as moisture, chemicals and various aggressive substances.

The Alpha caster is available in various sizes and load capacities. It is suitable for a wide range of different applications. The Alpha caster is robust, durable and can withstand the harsh conditions of industrial environments. In addition, this product family is easy to assemble and provides smooth movement of heavy loads.

Your advantages with our Alpha caster

- Robust all-rounder: suitable for your toughest requirements

- Flexible use: can be mounted on any type of equipment

- Long-lasting use: continuous use under demanding conditions

- Stainless steel version available: corrosion-free use even under difficult environmental conditions

If you have any questions or would like advice, our experts will be happy to help. Simply contact us using the contact form below and we will be happy to get in touch with you.

How much weight must casters and wheels normally be able to carry?

Casters and wheels must be able to carry different amounts of weight. However, the exact requirements depend on your individual application. Some casters and wheels only need to be able to carry light materials like boxes or drawers. Other casters and wheels need to be designed for heavy machinery, trucks, or even ships. In general, however, casters and wheels used in industry must be able to support weight loads ranging from several hundred kilograms to several tons at varying speeds and times of use. The exact specifications depend on the particular application and the customer's requirements.

How can casters and wheels be protected from wear?

There are a number of ways to protect casters and wheels from wear. For one, it's important to choose the right material. Also, choosing the right treads for your floor can increase the wear resistance of casters and wheels. In addition, regular maintenance can help extend the life of casters and wheels. Also, pay attention to how much weight a caster can support. Excessive load can wear out the caster quickly, and replacing casters and wheels can cost valuable time and money.

How important is the resistance of casters and wheels to chemicals?

Chemical resistance of casters and wheels in general industry is critical, as many industrial applications use chemicals and aggressive substances. Casters and wheels that are not chemical resistant can be damaged or have their performance compromised, resulting in lost productivity or even safety issues. Contact of casters and wheels with chemicals that degrade or weaken the materials can cause premature wear and failure of casters and wheels. For this reason, casters and wheels in industry often must be made of chemical-resistant materials such as stainless steel, polyurethane or rubber. Therefore, it is important that casters and wheels are selected for use in specific environments and applications to ensure maximum resistance to chemicals and aggressive substances.